Are your bolted joints secure? The integrity of countless structures, machines, and even everyday objects relies on properly tightened bolts. Achieving the correct tightness, however, is not a matter of guesswork. It requires understanding and applying the appropriate metric bolt torque specifications. Ignoring these specifications can lead to disastrous consequences, from loose components and vibrations to catastrophic failures.

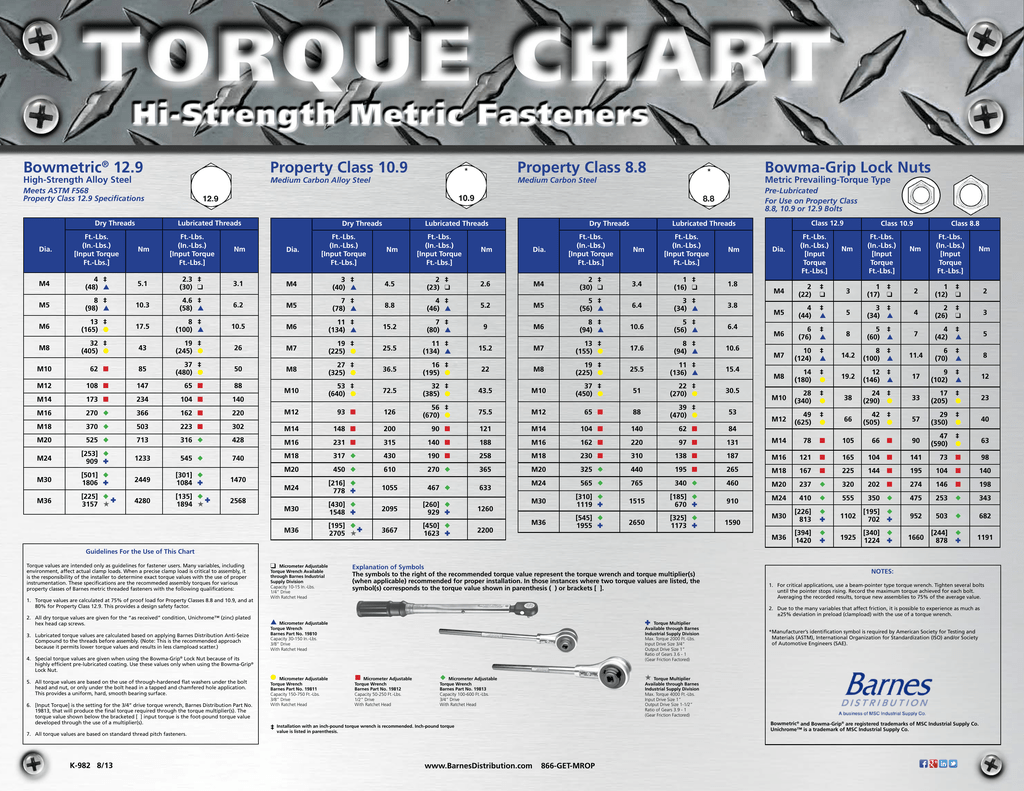

A metric bolt torque specification chart provides the prescribed tightening force, measured in Newton-meters (Nm), for specific bolt sizes and grades. These charts are essential tools for engineers, mechanics, and anyone working with bolted connections. They ensure consistent and reliable clamping force, preventing joint loosening and maximizing the lifespan of the assembled components. Finding the correct metric bolt torque values is paramount for maintaining structural integrity and operational safety.

The history of standardized bolt torque specifications is intertwined with the development of metric systems and the rise of industrial manufacturing. As global trade expanded, the need for uniform standards became critical. Organizations like the International Organization for Standardization (ISO) played a key role in developing internationally recognized torque guidelines, facilitating consistent assembly practices across different industries and regions. Metric bolt torque charts evolved from basic tables to sophisticated databases, incorporating factors like lubrication and thread pitch.

One of the main challenges with metric bolt torque charts is ensuring the correct chart is used for the specific application. Different materials, bolt grades, and plating require different torque values. Using the wrong specification can lead to over-tightening, which can strip threads or damage components, or under-tightening, which can result in joint failure. Furthermore, environmental factors like temperature and humidity can influence the effectiveness of applied torque.

Understanding bolt grades is critical when using a metric bolt torque specification chart. Bolt grades are indicated by markings on the bolt head and represent the tensile strength and yield strength of the bolt. Higher grade bolts can withstand greater torque values. For example, a common grade 8.8 bolt will have a different torque specification than a grade 10.9 bolt of the same size. Misinterpreting these markings or using an incorrect chart can compromise the integrity of the joint.

One benefit of using a metric bolt torque chart is ensuring consistent clamping force across multiple joints. This uniformity is essential for maintaining even load distribution and preventing stress concentrations. Another benefit is increased safety. Properly torqued bolts minimize the risk of joint failure, reducing the potential for accidents and equipment damage. Lastly, using accurate torque specifications can extend the lifespan of bolted connections by minimizing wear and tear caused by vibration and movement.

An effective action plan for implementing metric bolt torque specifications involves identifying the correct chart, selecting appropriate tools, and training personnel. Calibration of torque wrenches is vital for ensuring accuracy. Regular checks and audits can help maintain consistent practices and address any deviations.

When selecting a torque chart, consider the specific bolt material, grade, and size. Also, account for lubrication and environmental conditions. When applying torque, use a calibrated torque wrench and follow the manufacturer's instructions. Regularly inspect bolted connections for signs of loosening or damage.

Advantages and Disadvantages of Using a Metric Bolt Torque Spec Chart

| Advantages | Disadvantages |

|---|---|

| Consistent clamping force | Potential for using the wrong chart |

| Increased safety | Requires calibrated tools |

| Extended component lifespan | Environmental factors can influence results |

Best practices include using calibrated torque wrenches, cleaning threads before assembly, and applying lubricant where appropriate. Always consult the manufacturer's specifications and ensure personnel are trained on proper torque procedures. Documenting torque values can help track maintenance and identify potential issues.

Real-world examples include tightening cylinder head bolts in an engine, assembling structural steel beams, and securing wheel lugs on a vehicle. Each application requires specific torque values to ensure safety and performance.

Challenges can include variations in bolt quality, lubricant effectiveness, and operator error. Solutions involve implementing quality control measures, using consistent lubricants, and providing thorough training.

Frequently asked questions include: Where can I find a reliable metric bolt torque specification chart? How often should torque wrenches be calibrated? What is the difference between dry and lubricated torque values? How do I determine the correct bolt grade? What are the consequences of over-tightening or under-tightening? What factors affect the accuracy of torque measurements? How do I select the appropriate torque wrench for a specific application? What are the best practices for storing and maintaining torque wrenches?

Tips and tricks for working with metric bolt torque specifications include using a torque angle gauge for increased accuracy, applying lubricant consistently, and keeping torque wrenches clean and properly calibrated.

In conclusion, understanding and applying metric bolt torque specifications is crucial for ensuring the safety, reliability, and longevity of any bolted assembly. Utilizing a metric bolt torque specification chart is essential for achieving consistent clamping force and preventing joint failure. From automotive engines to bridges, proper torque is paramount. By following best practices, using calibrated tools, and understanding the various factors that influence torque, you can maintain structural integrity and avoid costly repairs or catastrophic failures. Take the time to familiarize yourself with the appropriate metric bolt torque specifications for your specific application and invest in quality tools. The benefits of proper bolt tightening far outweigh the cost of neglecting this crucial aspect of assembly. Make sure to regularly review and update your knowledge of bolt torque specifications and best practices, as this information can evolve with changes in technology and industry standards. Proper torque is an investment in safety, performance, and long-term reliability.

Decoding the toyota corolla check engine light a simple guide

Decoding behr downtown gray the versatile neutral

Bri sands las vegas a deep dive