Is your 175 Mercury outboard running hotter than a jalapeno in July? Before you start panicking, one of the most common culprits for overheating is a worn-out water pump impeller. This little rubber finned wheel is crucial for circulating cooling water through your engine. Ignoring a failing impeller can lead to catastrophic engine damage, so understanding how to diagnose and replace it is essential for every outboard owner.

The water pump impeller for a 175 Mercury, much like the heart of a circulatory system, keeps the engine cool under pressure. It draws water from the lower unit and pushes it through the engine block, absorbing heat and preventing overheating. Over time, the impeller's rubber vanes wear down, crack, or become brittle due to heat and chemical exposure. This reduces its efficiency, leading to decreased water flow and ultimately, a hotter engine.

Changing a 175 Mercury water pump impeller isn’t brain surgery, but it’s not exactly changing a light bulb either. Understanding the process, having the right tools, and paying attention to detail are key. A botched impeller replacement can lead to persistent cooling issues and even further damage. This guide will walk you through the process, from diagnosing a bad impeller to successfully installing a new one.

Historically, outboard motor cooling systems have relied on impellers. These small, but mighty components are vital to the longevity of any outboard engine. The design has evolved over time, with newer impellers using more durable materials and improved designs to withstand the harsh marine environment. The importance of regular impeller replacement cannot be overstated. It’s a relatively inexpensive preventative measure compared to the cost of a major engine rebuild.

One of the main issues related to 175 Mercury water pump impeller replacement is neglecting to do it regularly. Manufacturers typically recommend replacing the impeller every one to two years, or more frequently if the engine is used extensively in shallow or sandy waters. Running the engine with a worn-out impeller is like driving a car with low oil – it's just asking for trouble.

Benefits of a new impeller include consistent engine temperature, improved performance, and prolonged engine life. A well-functioning cooling system keeps your outboard running smoothly and efficiently, preventing costly repairs down the line. For instance, a new impeller ensures proper water flow, preventing overheating even during long runs at high speeds.

Action Plan for Impeller Replacement:

1. Gather necessary tools: service manual, lower unit gear oil, new impeller kit, gaskets, basic hand tools.

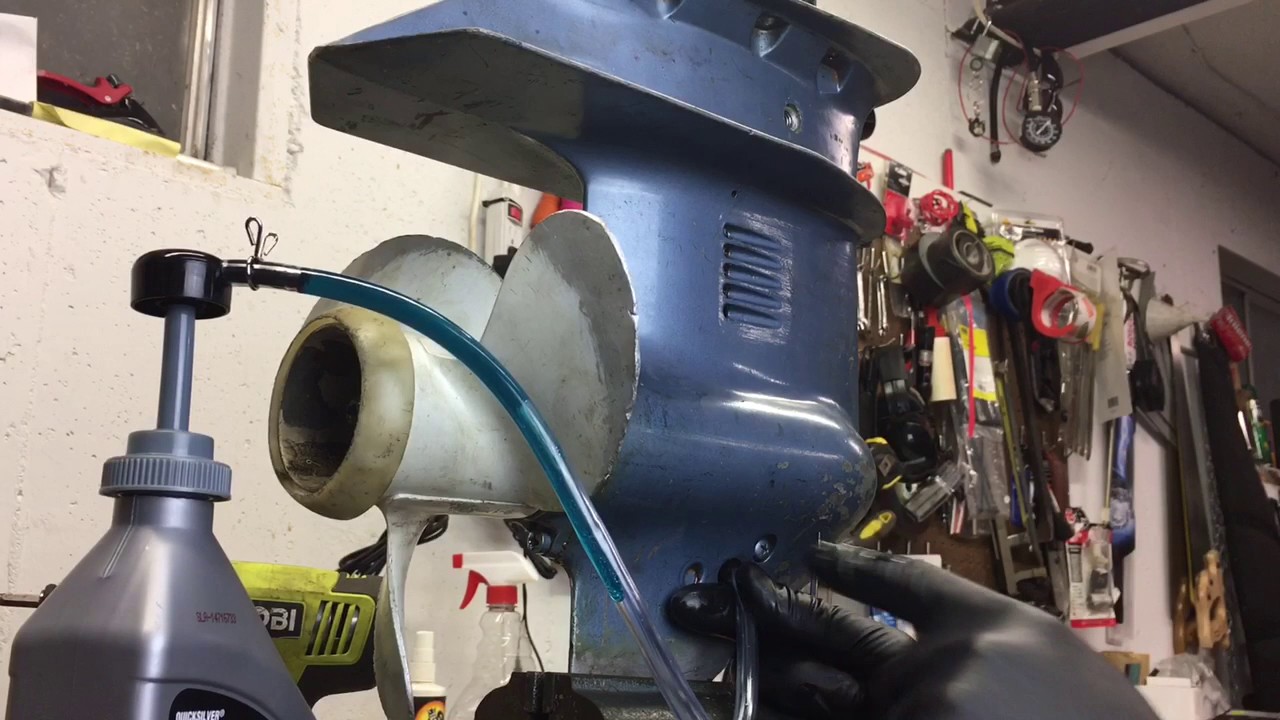

2. Drain the lower unit gear oil.

3. Remove the lower unit.

4. Locate and remove the old impeller.

5. Install the new impeller and gaskets, paying close attention to orientation.

6. Reassemble the lower unit.

7. Refill with fresh gear oil.Advantages and Disadvantages of DIY Impeller Replacement

| Advantages | Disadvantages |

|---|---|

| Cost savings compared to professional service. | Potential for damage if not done correctly. |

| Increased knowledge and understanding of your engine. | Time commitment required. |

FAQ:

1. How often should I replace my impeller? Generally, every 1-2 years.

2. What are the signs of a bad impeller? Overheating, weak telltale stream, steam.

3. Can I use any impeller? No, use the correct part number for your 175 Mercury.

4. What happens if I don’t replace my impeller? Engine overheating and potential damage.

5. Is it difficult to replace an impeller? Moderately challenging; requires mechanical aptitude.

6. Can I run my outboard without an impeller? Absolutely not!

7. What tools do I need? Basic hand tools, impeller kit, and service manual.

8. Where can I find a service manual? Online retailers, Mercury dealers.Tips and Tricks: Lubricate the new impeller with glycerin or soapy water for easier installation. Inspect the impeller housing for wear or damage. Always replace the gaskets. Double-check the impeller orientation before reassembling the lower unit.

In conclusion, replacing the water pump impeller on your 175 Mercury outboard is a crucial maintenance task. While it may seem daunting, understanding the process and having the right tools empowers you to maintain your engine's health. From preventing catastrophic overheating to ensuring peak performance, a fresh impeller is a small investment with significant returns. Don't wait for your engine to overheat; be proactive and replace your impeller according to the manufacturer's recommendations. Taking care of your outboard now will save you time, money, and headaches in the long run. This preventative maintenance will extend the life of your engine, keeping you on the water and enjoying those precious boating days for years to come. So grab your tools, consult your manual, and take charge of your 175 Mercury's health – your outboard will thank you for it.

Electrifying finance navigating the mn power credit union duluth landscape

Ann arbor stadium iii a vision for the future

Unveiling the legacy of the malacca sultanate