In the intricate dance of engineering and construction, seemingly small components often hold immense significance. Consider the humble bolt, a ubiquitous fastener found in everything from skyscrapers to spacecraft. When dealing with materials like copper, known for its malleability and conductivity, understanding the correct torque specifications becomes paramount. This exploration delves into the world of copper bolt torque, unraveling the importance of accurate tightening and the resources available, such as a copper bolt torque chart PDF, to guide this critical process.

Why is the precise tightening of a copper bolt so crucial? Over-torquing can lead to stripped threads, weakened bolts, and even material failure. Under-torquing, on the other hand, can result in loose connections, vibrations, and eventual joint separation. A properly torqued copper bolt ensures a secure and stable connection, safeguarding the integrity of the entire structure or system.

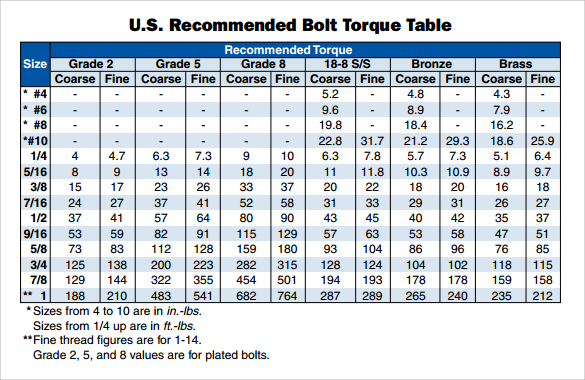

The quest for the ideal torque value often leads to the search for a comprehensive copper bolt torque specification document, sometimes available as a downloadable copper bolt torque chart PDF. These charts typically provide recommended torque values based on factors like bolt size, thread pitch, and the presence of lubricants. They serve as invaluable guides for engineers, technicians, and anyone working with copper fasteners.

While a generic copper bolt torque chart can provide a starting point, the specific application often dictates the final torque value. Environmental factors, such as temperature and humidity, can also influence the optimal torque. Consulting manufacturer specifications and relevant industry standards is always recommended to ensure the proper tightening of copper bolts in any given situation.

Understanding the historical context of torque specifications reveals a journey of continuous refinement. Early fastening methods relied heavily on experience and intuition. As engineering principles evolved, the need for standardized torque values became apparent. Today, various organizations, including fastener manufacturers and engineering societies, contribute to the development and dissemination of torque guidelines.

One of the main issues concerning copper bolt torque charts, especially those distributed as PDFs, is ensuring they are up-to-date. Using outdated information can lead to incorrect torque application. It is essential to verify the source and date of any copper bolt torque chart PDF to guarantee accuracy and reliability.

Benefits of using a reliable copper bolt torque specification resource include: preventing joint failure, ensuring consistent clamping force, and extending the lifespan of the fastened components. For example, in electrical applications, proper torque prevents overheating and ensures a reliable connection, minimizing the risk of fire hazards.

Advantages and Disadvantages of using a Copper Bolt Torque Chart PDF

| Advantages | Disadvantages |

|---|---|

| Easy access and portability | Potential for outdated information |

| Provides a quick reference guide | May not cover all specific applications |

| Can be printed and used on-site | Requires verifying the source and accuracy |

Best Practices for Using Copper Bolt Torque Charts:

1. Verify the chart's relevance to your specific application.

2. Ensure the chart is up-to-date and from a reputable source.

3. Clean and lubricate threads as recommended.

4. Use a calibrated torque wrench for accurate tightening.

5. Consult manufacturer specifications for any deviations.

Frequently Asked Questions:

1. Where can I find a copper bolt torque chart PDF? - Search reputable fastener manufacturer websites and industry organizations.

2. What factors influence copper bolt torque? - Bolt size, thread pitch, lubricants, and application environment.

3. What are the risks of over-torquing? - Stripped threads, bolt failure, and damage to the fastened materials.

4. What are the risks of under-torquing? - Loose connections, vibrations, and joint separation.

5. How do I choose the right torque wrench? - Select a wrench with the appropriate torque range and accuracy for your application.

6. How often should torque wrenches be calibrated? - Calibration frequency depends on usage but is typically recommended annually.

7. Can I use a steel bolt torque chart for copper bolts? - No, different materials have different torque requirements.

8. What are the best lubricants for copper bolts? - Consult manufacturer recommendations for suitable lubricants.

Tips and Tricks: When working with copper, it is crucial to be mindful of its softness. Avoid over-tightening, and always use a calibrated torque wrench to achieve the precise torque value. Regularly inspect fastened connections for any signs of loosening or damage.

In conclusion, understanding and applying the correct torque specifications for copper bolts is crucial for ensuring the safety and reliability of any assembly. From preventing catastrophic failures to maintaining optimal performance, the seemingly simple act of tightening a bolt holds significant weight. Utilizing resources such as a copper bolt torque chart PDF, adhering to best practices, and continually seeking updated information empower us to master this fundamental aspect of engineering and construction. By embracing precision and knowledge, we can ensure that our structures stand strong and our systems function flawlessly, all thanks to the proper torque applied to those unassuming copper bolts. Take the time to research and understand the specific requirements of your application. Consult manufacturer guidelines and reputable sources for accurate torque values. By prioritizing proper torque techniques, you invest in the longevity and safety of your projects.

Unveiling skip bin secrets fascinating facts you need to know

Ada wong resident evil 4 remake cosplay a deep dive

Trees poetry explored joyce kilmers famous poem