Powering a detached garage, workshop, or even a tiny home nestled 200 feet from your main electrical panel? You're going to need a subpanel, and figuring out the right wire size for that 100-amp subpanel over that distance is crucial. Getting it wrong can lead to inefficient power delivery, overheating wires, and even fire hazards. This comprehensive guide breaks down everything you need to know about selecting the correct conductor for a 100 amp subpanel 200 feet away.

Imagine trying to run power-hungry tools in your new workshop, only to find they’re constantly tripping the breaker or running at less than full power. That frustrating scenario is a common consequence of undersized wiring. The longer the distance, the more significant the voltage drop – the loss of electrical pressure – becomes. A 200-foot run presents a considerable challenge, demanding careful wire gauge selection to maintain proper voltage at the subpanel.

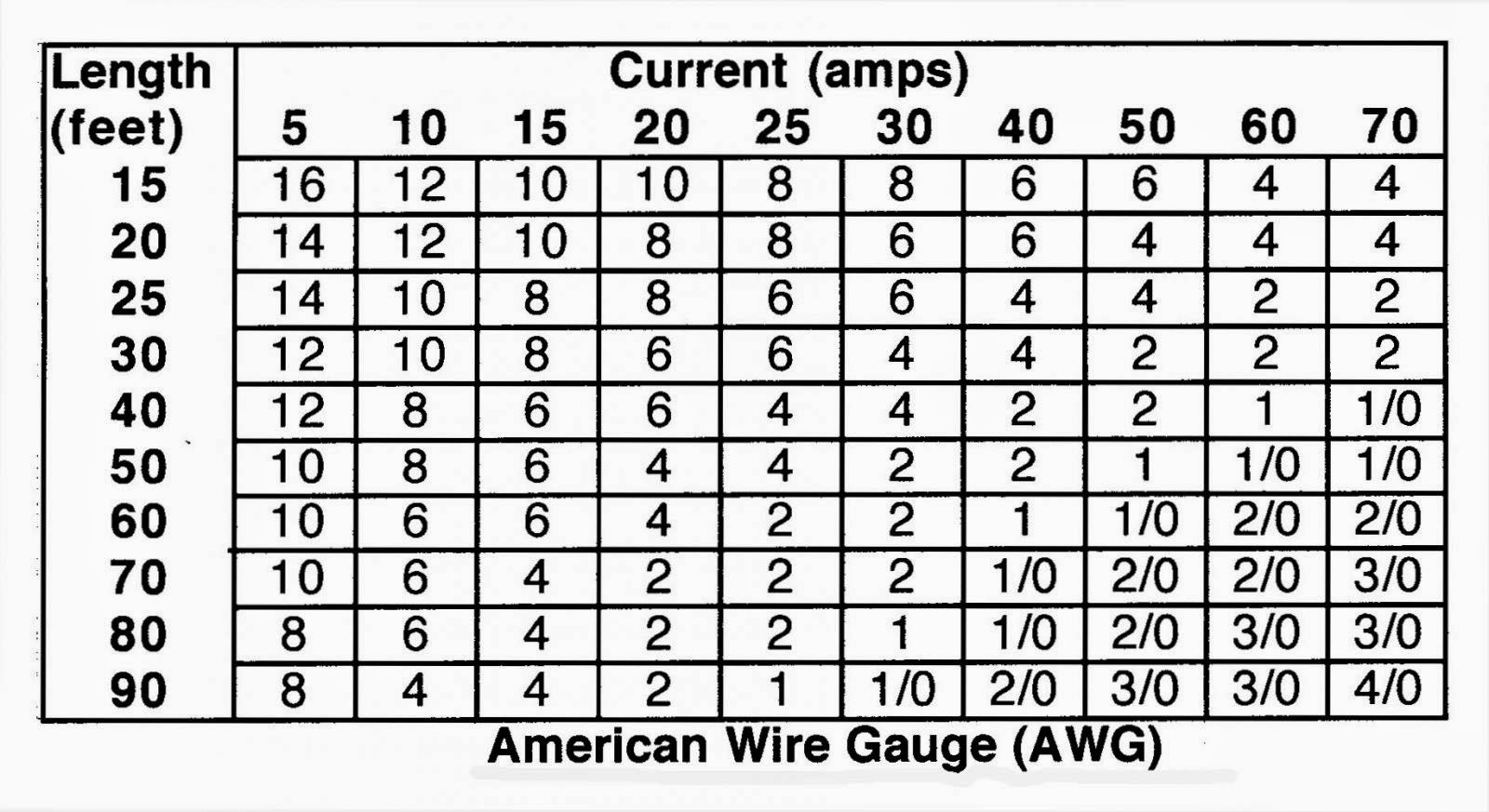

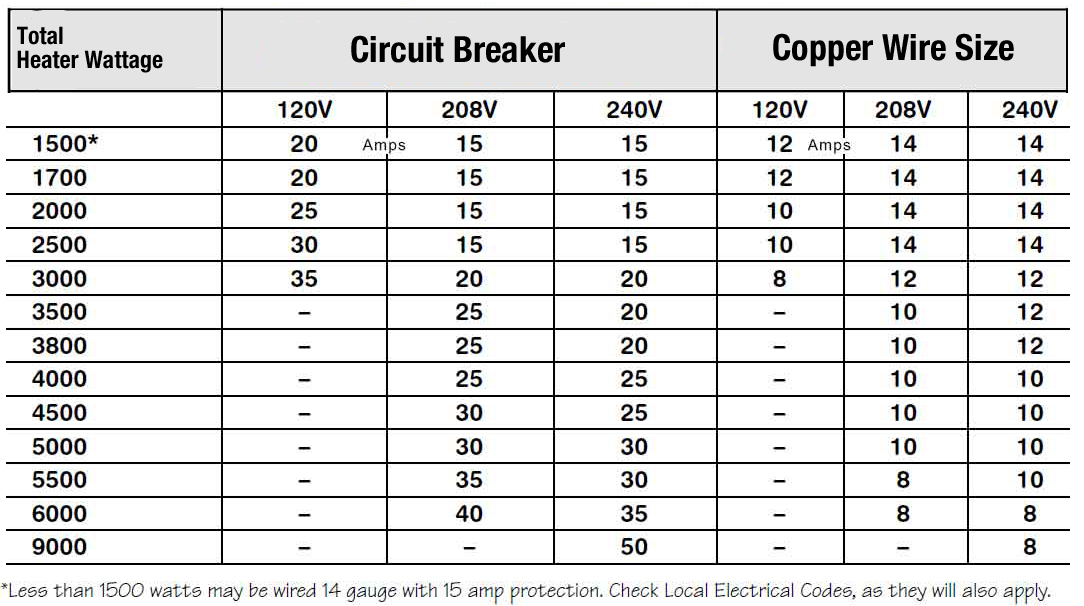

Determining the appropriate wire size for a 100-amp subpanel 200 feet away isn't just about matching the amperage; it's about mitigating voltage drop. The National Electrical Code (NEC) recommends keeping voltage drop to a maximum of 3% for branch circuits and 5% for feeders (combined feeder and branch circuit). Failing to adhere to these guidelines can result in appliance damage, inefficient operation, and potential safety risks.

While the NEC provides general guidelines, calculating the exact wire size requires understanding factors like the metal of the conductor (copper or aluminum), the ambient temperature, and the load the subpanel will carry. Online calculators and resources can assist in this process, but understanding the underlying principles is essential for ensuring a safe and reliable installation.

This guide will equip you with the knowledge and resources to confidently tackle the task of wiring your 100-amp subpanel 200 feet away. From understanding voltage drop calculations to exploring different wiring materials, we’ll cover all the essential information you need to power your project safely and efficiently.

Historically, understanding wire gauge and its relationship to distance and amperage was a specialized skill possessed primarily by electricians. Today, with readily available resources and online calculators, homeowners can make informed decisions about their electrical projects. However, proper understanding of the underlying principles remains critical for safe and code-compliant installations.

One major issue related to incorrect wire sizing for a 100-amp subpanel 200 feet away is excessive voltage drop. This can lead to dimmed lights, underperforming appliances, and overheating of the wires, potentially creating a fire hazard. Another common issue is using aluminum wiring improperly. While cheaper than copper, aluminum requires specialized connectors and techniques to prevent corrosion and ensure a reliable connection.

Advantages and Disadvantages of Different Wire Types

| Wire Type | Advantages | Disadvantages |

|---|---|---|

| Copper | Excellent conductivity, easier to work with | More expensive than aluminum |

| Aluminum | Lighter and less expensive | Requires special connectors, potential for corrosion |

Best Practices:

1. Consult the NEC and local codes for specific requirements.

2. Use an online voltage drop calculator to determine the appropriate wire size.

3. Always choose copper wiring for reliability unless you are experienced with aluminum wiring installation.

4. Properly size the conduit to accommodate the chosen wire gauge.

5. Hire a qualified electrician for the installation if you are not comfortable working with electricity.

FAQ:

1. What is voltage drop? (Loss of electrical pressure over distance)

2. Can I use aluminum wire? (Yes, with proper connectors and techniques)

3. What size conduit do I need? (Depends on the wire gauge)

4. Do I need a permit? (Check with local authorities)

5. What is the NEC? (National Electrical Code)

6. How do I calculate voltage drop? (Use an online calculator or formula)

7. What are the signs of undersized wiring? (Dim lights, tripping breakers, overheating appliances)

8. How can I find a qualified electrician? (Check online directories and local referrals)

Tips and Tricks:

Oversize the wire slightly to accommodate future expansion. Consider using conduit to protect the wires from damage.

Selecting the correct wire size for a 100-amp subpanel 200 feet away is paramount for safe and efficient power distribution. Understanding voltage drop, wire gauge selection, and NEC guidelines are essential for a successful installation. While online resources and calculators can simplify the process, consulting with a qualified electrician is always recommended, especially for those unfamiliar with electrical work. Properly sizing your wiring ensures that your detached structures or appliances receive the power they need without compromising safety or efficiency. This comprehensive guide provides the necessary information to embark on your project with confidence, empowering you to make informed decisions and ensure a reliable and long-lasting electrical system. Ignoring the intricacies of wire sizing can lead to a host of problems, from underpowered appliances to potential fire hazards. Taking the time to understand these concepts will not only enhance the safety of your electrical system but also contribute to the overall longevity and performance of your connected devices and structures. By prioritizing proper wire sizing, you’re investing in the safety and efficiency of your electrical system for years to come. Don't cut corners; make informed decisions and consult a professional when needed.

South carolina power outages your guide to staying lit

Unlocking grayson lake state park campground your kentucky adventure awaits

Unlocking perfect hues the power of custom color match paint

.jpg)